The cutting technique known as waterjet cutting is one of several types of machining used in many industries. In the manufacturing process, a waterjet cutter is used to cut and shape various materials. It’s a very flexible and useful instrument that offers several obvious benefits.

In this article, you will know the core money-saving benefits of CNC waterjet cutting technology.

What exactly is Waterjet Cutting?

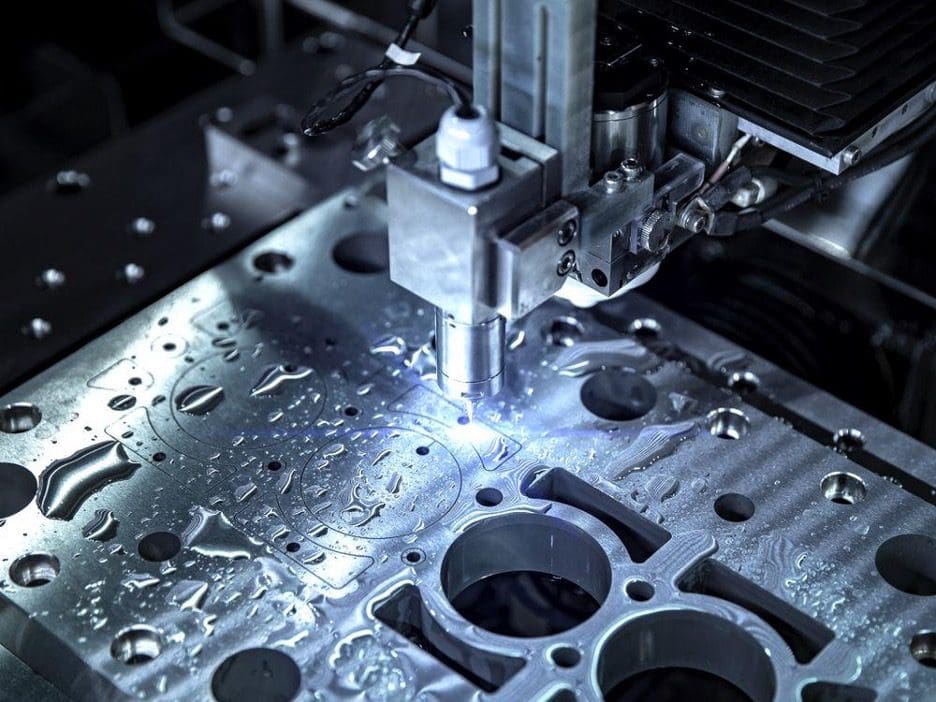

With a carbide nozzle, fine garnet abrasive, and high-pressure water jet stream, waterjet cutting is a metal-cutting process used in metal manufacturing. The process is only an extreme and sped-up version of natural erosion. The procedure is sped up by using a water jet containing abrasive particles.

How Does Waterjet Cutting Work?

In contrast to more conventional saws, a waterjet cutter makes use of water to make the cuts. Water is forced through a narrow opening at high pressure, creating a jet that can make clean enough cuts to be used in material shaping. To make clean cuts in softer materials like rubber, it’s possible to use solely water as a cutting medium. Incorporating abrasives into the water during the waterjet cutting process allows for the processing of even harder materials.

Who Can Take Advantage of Waterjet Cutting?

Companies and individuals that need to cut through tough materials might benefit from waterjet cutting. And it’s a quick procedure that might end up saving you money and time. Because of the high-pressure water stream’s clean and accurate cutting, less material is wasted in the cutting process. The following sectors can benefit from waterjet cutting:

- Fabricators

- Designers of landscapes

- Machinists’ shops

- Designers of hardscapes

- Travertine businesses

- Fabricators of metal

- Builders of Swimming Pools

- Artists

- Designers of the outside

- Auto repair shops

- Contractors in general

Plus a lot more!

Advantages of Using Computer Numerically Controlled Waterjet Cutting

Waterjet cutting has the benefit of being able to cut nearly any material used in conventional machining and manufacturing. It may be used in virtually any industry.

When compared to more conventional ways of cutting, waterjet cutting has the advantage of minimizing the corrosive effects of heat. After generating heat by abrasive erosion, the water rapidly dissipates it. Because of the waterjet’s ability to do the cold cutting, the material is little changed, and the likelihood of warping, cracking, or breaking is greatly reduced. You may save money with waterjet cutting since it eliminates the need for further operations.

Here are a few reasons a CNC waterjet is the best option if you’re considering CNC machines:

Superior Cut-End Finish Boosts Efficiency

Putting the finishing touches on a project that was created with a CNC machine is often necessary to make sure the client is satisfied. But a waterjet can create a perfect cut the very first time.

Final sanding of the cut is no longer required.

The Capability to Cut a Wide Range of Materials

A computer numerically controlled waterjet (CNC) cutter is unparalleled in its cutting flexibility. You may stop looking for freelance cutters immediately.

In addition, this is a good time to pick up side gigs. That results in more than just financial savings. While doing so, you also boost income.

Saving money on the environment doesn’t mean sacrificing quality.

Since no waste gases are produced during waterjet cutting, it has no adverse environmental effects. You needn’t give a second thought to potential ecological consequences.

This means there is no need to allocate funds toward environmentally responsible initiatives.

A lot of water seems to be wasted by waterjets, right?

No. What little water they have is put to good use.

Reduce your raw material expenditures.

The cutting width of waterjet cutters is quite small. This shows that they are gradually decreasing the amount of trash they are throwing away. You’ll save money on raw ingredients, too.

Increasing the pace at which you cut increases your efficiency even further.

A waterjet’s speed of cutting is unrivalled. It is one of the fastest CNC machines in the market, capable of cutting at up to 2700 inches per minute (IPM).

Because of this, you might get more done in less time. Your operating expenses will go down. The efficiency gains from using waterjet cutting are doubled because the cut is accurate the first time around.

Quickly release your prototypes.

It might take a while to finish a prototype. However, waterjets are faster, thus less time is needed.

When putting together many prototypes for testing, is a huge timesaver. The time to introduce a product to consumers is reduced. Saving time and money at the prototype phase is tough to calculate.

You might save a lot of time and money by using a CNC waterjet. And now that you know their process, you can evaluate its viability for your own business.

No need to dig any sort of hole to use as a beginning point.

For certain tools, initial holes need to be drilled before production can begin. When using waterjet cutting, this is not the case. That’s a further reduction in cost and effort.

Additional advantages of using waterjet cutting in metal fabrication include:

- Accepted by computerized contouring tools

- Easy to implement into flexible production setups

- The standard CAD/CAM systems provide a basic programming interface.

- Layered materials may be cut easily

- Supports rapid iteration

- The speed of which is unmatched by most conventional cutters

- There is zero strain on the body.

Final Words

To cut through tough materials, waterjet cutting may be your best option. This technique uses a high-pressure water jet to sever various materials, including metal, plastic, and more. It’s a versatile technique that can serve a variety of functions. Keep learning all you can about CNC waterjet cutting and contact Techni waterjet to get a price quote.